The Importance of the Crankshaft in Diesel Engines

The crankshaft is an essential component of any engine, especially in the world of diesel engines. It serves as the heart of the engine, converting the linear motion of pistons into rotational motion, which ultimately powers the vehicle. Understanding the function, design, and maintenance of the crankshaft in engine systems is crucial for both automotive enthusiasts and professional mechanics alike. In this comprehensive article, we will delve into the intricacies of the crankshaft, its significance in diesel engines, and best practices for maintenance.

What is a Crankshaft?

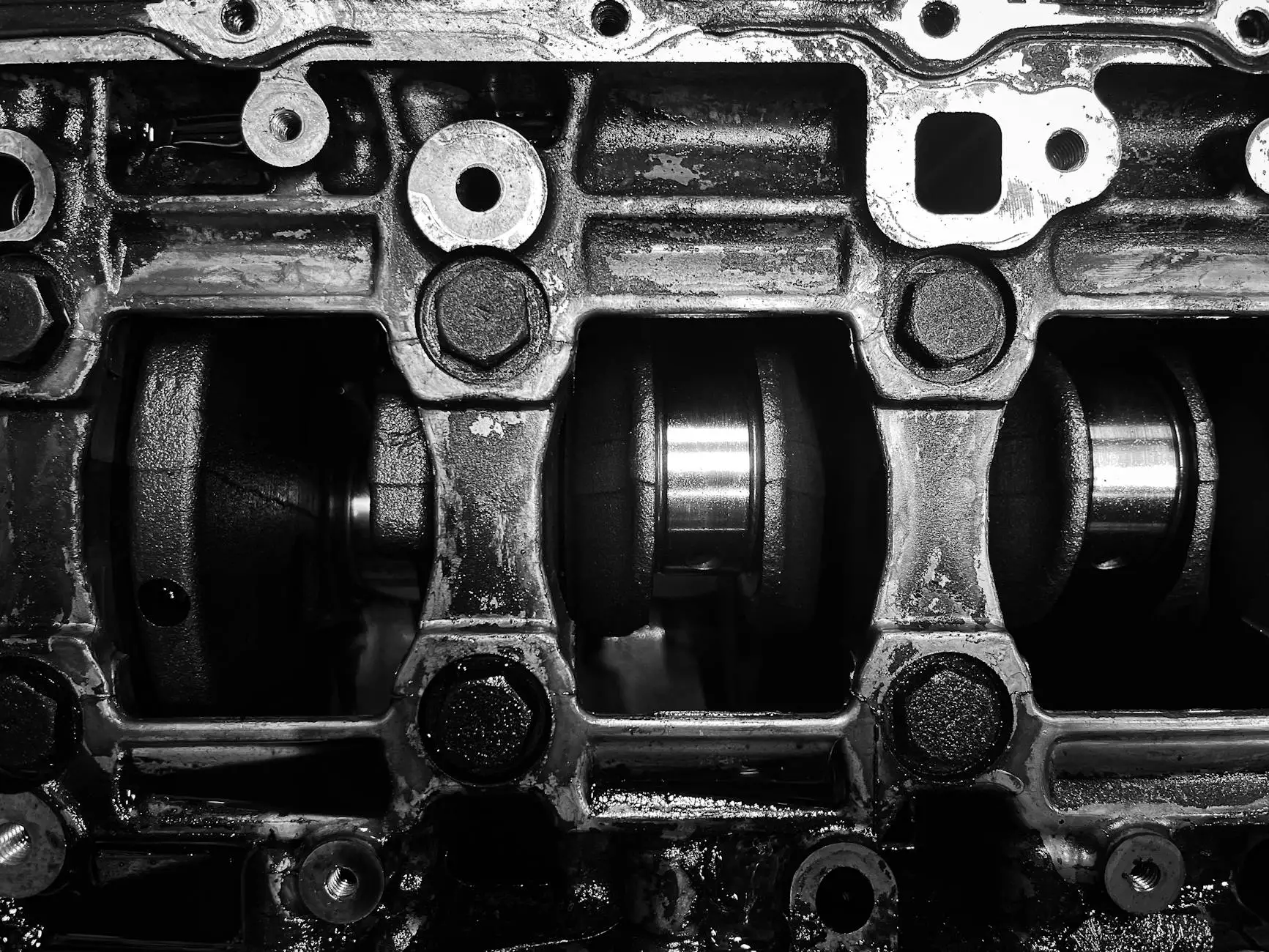

The crankshaft is a large mechanical component made of high-strength steel or cast iron. It plays a pivotal role in the internal combustion engine. Essentially, it transforms the reciprocating motion of pistons into rotational motion. The crankshaft is positioned at the bottom of the engine block and is connected to several other engine components, including the flywheel and the camshaft.

Design and Structure of the Crankshaft

The design of the crankshaft is crucial for its functionality. It consists of the following key components:

- Main Journal Bearings: These bearings allow the crankshaft to rotate smoothly within the engine block.

- Crankpins: These are the points where the connecting rods attach and convert the linear motion of pistons into a rotational motion.

- Counterweights: These help balance the crankshaft, reducing vibrations during engine operation.

- Flange: This part connects the crankshaft to the flywheel or flexplate.

How Does the Crankshaft Work?

The operation of the crankshaft in engine systems can be described in several steps:

- The pistons move downwards due to combustion.

- This movement is transferred to the connecting rods and then to the crankpins on the crankshaft.

- The crankshaft rotates, converting linear motion into rotational motion.

- The rotational power is transmitted to the flywheel, which assists in smooth engine function.

- Finally, this power is transferred to the drivetrain to propel the vehicle.

The Role of the Crankshaft in Diesel Engines

In diesel engines, the demands on the crankshaft are particularly high due to the increased pressure and temperatures involved. Diesel engines operate at higher compression ratios than gasoline engines, requiring a crankshaft that can withstand greater stress and strain.

Durability and Strength

Due to the nature of diesel combustion, which results in higher torque at lower RPMs, the crankshaft must be designed to endure significant forces. Heavy-duty crankshafts are often used in diesel engines, made from forged steel to provide the necessary strength. This durability ensures the engine's longevity and performance under strenuous conditions.

Precision Engineering

Moreover, the precision engineering involved in producing a crankshaft is of paramount importance. Any imbalance or misalignment can lead to severe mechanical failures. Hence, meticulous attention to detail during manufacturing and installation is crucial.

Maintenance of Crankshafts

To ensure the longevity and efficiency of the crankshaft, regular maintenance is key. Here are some essential maintenance tips:

Regular Oil Changes

Engine oil lubricates the crankshaft and reduces friction. Regular oil changes ensure that the crankshaft operates smoothly and prevents wear and tear. It is advisable to follow the manufacturer’s recommended oil change intervals.

Monitor Engine Vibrations

Unusual vibrations can indicate crankshaft issues. If you notice excessive vibrations in the engine, it may be time to check the crankshaft and related components for balance and alignment.

Inspect Bearings and Clearances

Regular inspections of main bearings and clearances can prevent catastrophic failures. If bearings show signs of wear, they should be replaced immediately to avoid further damage to the crankshaft.

Use Quality Replacement Parts

When replacing components associated with the crankshaft, such as bearings and seals, using high-quality parts is essential. Quality replacements contribute significantly to the durability and efficiency of the engine.

Choosing the Right Crankshaft for Your Diesel Engine

Selecting the appropriate crankshaft in engine systems can have a profound impact on performance and reliability. Here are vital factors to consider:

Engine Specifications

Before choosing a crankshaft, one must understand the engine’s specifications, including its displacement and type (e.g., inline, V-type). This will ensure compatibility and optimal performance.

Intended Use

The application of the engine—whether for everyday use, heavy-duty work, or racing—will dictate the kind of crankshaft required. For instance, high-performance applications necessitate specially designed crankshafts capable of handling increased stresses.

Material Type

Crankshafts come in various materials. While cast iron is common, many high-performance and heavy-duty applications favor forged steel for its superior strength and resilience.

Innovations in Crankshaft Design

The automotive industry continuously evolves, and so do the designs and materials used in crankshafts. New innovations focus on optimizing performance, efficiency, and sustainability. Here are a few notable advancements:

Lightweight Materials

New materials and manufacturing processes are allowing for lighter crankshafts that maintain strength and durability, contributing to overall vehicle performance and fuel efficiency.

Smart Technologies

Integration of smart sensors within crankshaft systems allows for real-time performance monitoring. This technology aids in predictive maintenance, reducing downtime and enhancing reliability.

Final Thoughts

The crankshaft in engine systems is undeniably one of the most critical components of diesel engines. Its ability to convert linear motion into rotational power is vital for engine performance. As this article has shown, understanding the crankshaft’s design, function, and maintenance is essential for anyone involved in the diesel engine industry.

Frequently Asked Questions (FAQs)

1. What are the signs of a failing crankshaft?

Signs of a failing crankshaft include unusual noises (thumping or knocking), engine vibrations, oil leaks, and warning lights on the dashboard.

2. How can I improve the lifespan of my crankshaft?

Improving crankshaft lifespan requires regular maintenance, using quality engine oils, and consistent inspections to identify potential issues early.

3. Why is balancing important in a crankshaft?

Balancing is crucial as it minimizes vibrations, reduces wear on engine parts, and enhances overall engine performance.

4. Can a damaged crankshaft be repaired?

In some cases, a damaged crankshaft can be repaired through machining. However, if the damage is extensive, replacement is often the better option.

In conclusion, the propensity for ensuring that your crankshaft is in optimal condition is imperative for longevity and efficiency in diesel engines. Fostering an environment for regular checks, utilizing quality components, and understanding the complex role of the crankshaft will drive performance and reliability.